Product Features

The #1 Choice for Protection Against Electric Shock Drowning

The SENTINEL™ Electrical Insulation Socket is a patented, Australian-made innovation and the recognised Game-Changer in achieving superior safety and compliance for pool and spa environments. Designed as a modern, efficient, and cost-effective alternative to traditional Equipotential Bonding (Grounding/Earthing), the SENTINEL™ is the number one choice for protection against electric shock drowning.

The SENTINEL™: your gateway to peace through innovation, epitomising the fusion of simplicity, practicality, and a safety-first principle.

- Unsurpassed Insulation: Manufactured with an emphasis on superior insulation, the SENTINEL™ Electrical Insulation Socket offers unprecedented safety, allowing you to use your swimming pool or spa with confidence.

- Resilient Construction: The SENTINEL™ is fabricated to endure routine usage while upholding their function and safety measures. Their modular design allows for customisation, demonstrating their robustness and versatility.

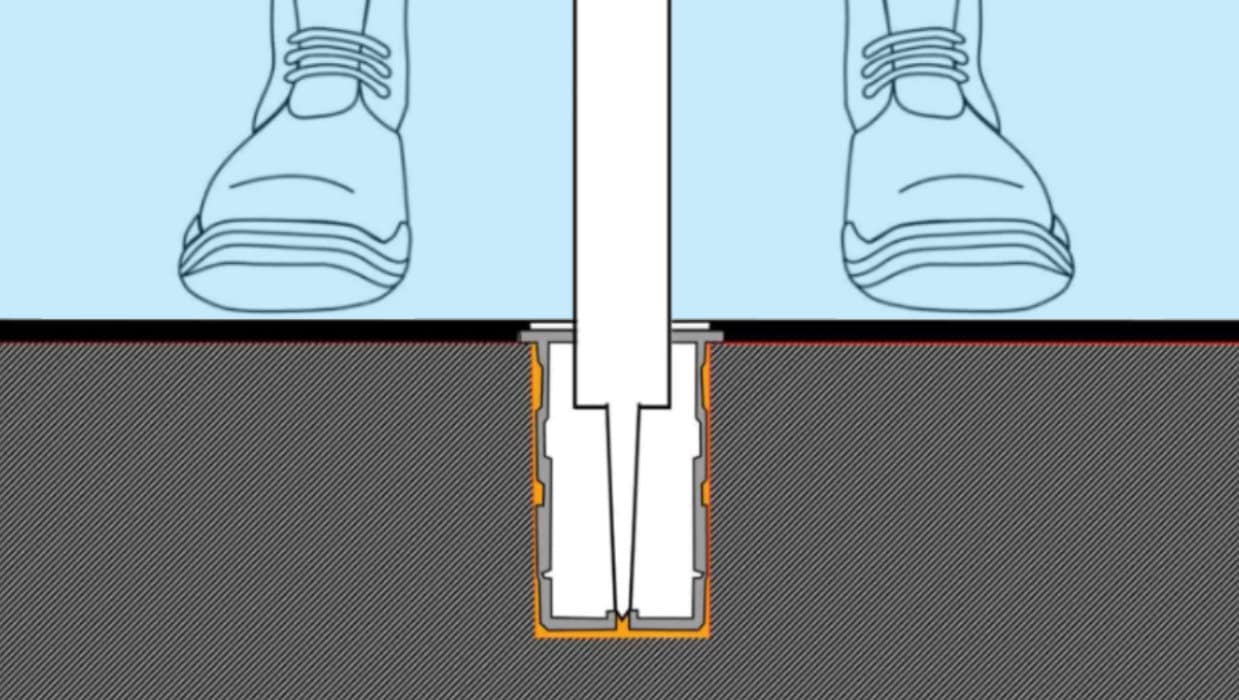

- Straightforward Installation: The SENTINEL™ promises a seamless installation process, minimising setup time. The electrical insulation sockets are designed to be installed using our SENTINEL™ Guide Tool, air vent apertures in the socket flange are to aid in the flow of the Pure Epoxy Fixing Material, and a bayonet fitting of the socket sections for secure usage, contributing to a hassle-free setup and enabling you to relish the convenience it delivers quicker.

Safeguard Against Electric Shock Drowning

The SENTINEL™ Electrical Insulation Socket goes beyond being a simple socket; it’s your shield against electric shock drowning. This highly advanced socket becomes double insulated once fixed in a core hole with Pure Epoxy Fixing Material, providing a secured electrical environment around pools for your home or business establishment. It’s the serenity that comes with knowing that everyone, including children, pets, or any individual present, is safeguarded against the potential for electric shock drowning.

How It Works

The SENTINEL™ functions on a fundamental yet ingenious concept of providing superior electrical insulation. It’s resistant to damage, particularly amid groundworks like renovations that could potentially harm the earthing grid connections. Due to its modular design, the SENTINEL™ can be extended or customised to satisfy various requirements. Moreover, its robust composition guarantees durability even with regular use while maintaining its remarkable safety specifications.

Both handy – given its easy installation and user-friendly design – and designed to be hidden by a cover plate surrounding the item being embedded into the socket with grout. Embrace a heightened level of electrical safety with the SENTINEL™, each use echoing its excellent blend of convenience and innovation.

Who Should Use It

The SENTINEL™ is ideal for those in pursuit of a significantly improved electrical safety in their pool areas. It has particular advantages for:

- Families who wish to secure their loved ones from any potential electric shock drowning incidents.

- Workplaces, to ensure the safety of employees and diminish electricity-related incidents.

- Hotels and public areas, to protect both staff and visitors and emphasise a commitment to safety and the well-being of others.

Quick Comparison — Why SENTINEL™ is Better

- Safety mechanism: Insulates at the socket (permanent barrier) vs. coatings/caps (damage‑prone) vs. bonding (works but wiring‑dependent).

- Compliance clarity: Deemed‑to‑satisfy pathway + visual proof for certifiers; bonding needs electrical documentation; coated spigots rely on sleeve integrity.

- Time & cost: No earthing conductors for the spigot/post → quicker and usually cheaper than bonding; avoids coated‑spigot rework risk.

- Retrofit‑friendly: Easier than extending bonding conduits; modular to scale height; guide tool streamlines core drilling.

- Aesthetics & finishes: Use popular stainless finishes – insulation is hidden; coatings can constrain look and degrade over time.

- Maintenance: Minimal (keep the cover clean) vs. coating inspections/replacement or bonding checks after alterations.

Select a Product Features Video to Play

Frequently Asked Questions

| Question | Answer | Category |

|---|---|---|

| In simple terms, how is the SENTINEL™ different? | SENTINEL™ insulates at the socket—where the metal meets the structure—so the whole installed element becomes double‑insulated when installed with approved pure epoxy. Non‑conductive spigots depend on surface sleeves/coatings that can chip, scratch, or lose caps. Equipotential bonding is a wiring method that requires a licensed electrician to connect metal parts to earth. | Basics |

| Why is insulating at the socket safer than relying on coated spigots? | Because it bypasses the main failure modes of coatings and caps. Even minor scratching, UV/chemical exposure, missing grub‑screw caps or normal wear can compromise spigot coatings. SENTINEL™ eliminates those surface dependencies by isolating the element within an insulated socket. | Safety |

| How does SENTINEL™ compare with equipotential bonding for safety? | Bonding aims to keep all conductive parts at the same potential via wiring. It works when installed and maintained correctly, but it’s more complex, costlier and can be difficult to retrofit. SENTINEL™ prevents hazardous touch voltages at the source by providing a permanent insulating barrier—no earthing conductors required for the spigot/post itself. | Safety |

| Is the SENTINEL™ a compliant pathway? | It is promoted as a deemed‑to‑satisfy alternative for metallic parts within arm’s reach of the pool/spa. It’s designed specifically to address safety around extraneous conductive elements and is accompanied by clear guidance, testing notes, and a visual confirmation method for certifiers. | Compliance |

| What’s the visual proof for certifiers and inspectors? | Lift the cover plate: the black SENTINEL™ flange is visible as a simple, reliable confirmation of insulation in situ. This is quicker and clearer than inferring performance from a coating or requesting bonding paperwork. | Compliance |

| Does the SENTINEL™ save time and cost? | Yes. There’s no earthing conductor to install for the spigot/post, and no electrician visit for that task. Core drill, epoxy the SENTINEL™, grout the element, and you’re done. Compared with bonding, this typically reduces coordination, labour and delays. Compared with coated spigots, it also reduces lifecycle risk of rework. | Installation |

| Is the SENTINEL™ easier to retrofit? | Usually yes. Extending or repairing bonding after the fact can be intrusive and expensive. SENTINEL™ can be installed into a standard Ø76–77 mm core hole and scaled/lengthened with modular sections to suit the application. | Installation |

| What about durability over time? | SENTINEL™ is hidden beneath the cover plate and isn’t exposed to UV or surface abrasion like sleeves/coatings. Once epoxied and grouted correctly, it provides a robust, permanent insulating barrier. | Durability |

| Does it limit my finish choices? | No. SENTINEL™ is inclusive of popular stainless finishes (polished/brushed). Because the insulation is at the socket, you’re free to use metal finishes that suit the design. | Aesthetics |

| Is there independent testing? | Yes. The brochure references independent testing and on‑site demonstrations. It also clarifies correct installation using approved pure epoxy and the dedicated guide tool for drilling and placement. | Compliance |

| What installation aids are available? | The SENTINEL™ Guide Tool assists with drilling a Ø77 mm core hole and holds the flange while injecting epoxy through the base aperture. The modular body uses a bayonet join with vent apertures to help epoxy rise. | Installation |

| What maintenance is required? | Minimal. Keep spigots and cover plates free of debris so the system works as intended. There’s no sleeve or coating to periodically check for chips or UV damage. | Maintenance |

| Can I use the SENTINEL™ together with equipotential bonding? | Yes. You can use the SENTINEL™ as an added failsafe—useful where an earthing grid could be compromised later (movement, corrosion, earthworks) or where regulations and designers prefer layered protection. | Compatibility |

| Where does the SENTINEL™ make the biggest difference versus coated spigots? | In real‑world conditions: busy pool areas, exposure to sun and chemicals, and places where grub‑screw caps can be left out or wear out. SENTINEL™ removes these weak points by insulating at the structural interface. | Safety |

| What applications might it cover beyond pool‑fence spigots? | Posts, grab rails, ladders, handrails, sockets and similar extraneous conductive elements within arm’s reach of pools and spas. The modular body allows height scaling; custom options are available. | Applications |

| What products and consumables must I use? | Use the approved pure epoxy adhesive per instructions (e.g., TSA Pure Epoxy 21) and follow the official installation steps. Using incorrect products may compromise performance and compliance claims. | Products |

| Who benefits most from choosing the SENTINEL™? | Homeowners: safer pool surrounds without visible trade‑offs or finish restrictions. Installers/Builders: faster installs, fewer coordination points, clear visual proof. Certifiers: quick on‑site verification (lift the cover plate; see the flange). | Audience |